On the Production Editing toolbar, there are several tools that are part of the Production Mapping extension, but it also includes ArcMap editing tools. We also have a team of experienced engineers on-site that can refine this process still further, using their knowledge and skills to fine tune and perfect tool designs.ArcMap editing tools and the Production Editing toolbarĪvailable with Production Mapping license. This patented valve utilizes the differential pressure from the hydrostatic head above the pump to open a communication path between the annulus and tubing once the pumping system is turned off.

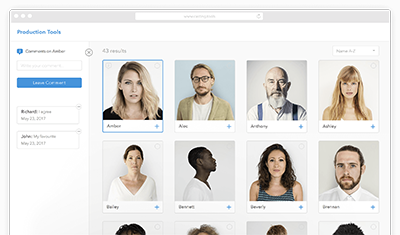

PRODUCTION TOOL SOFTWARE

We then carry out the process using our tooling software systems (including DEFORM), which enables our tool design process, analysis and testing to be carried out efficiently on-screen, rather than in the tool-room. Production Tool Solution ESP Pressure Actuated Relief Valve is a field-proven tool used to prevent solids/sand from settling on top of both progressing cavity pumps and electric submersible pump during shut down. Production planning originated to optimize the manufacturing process, and today its general logic is applied in various forms to design. Production planning helps organizations make the production process as efficient as possible.

This might either be a one-off charge or an agreement to amortise the cost of tooling across the lifetime of the project. Production planning is the act of developing a guide for the design and production of a given product or service. We work with each customer to explain how our tooling costs are calculated and then find the solution that works best for both parties.

Our approach to tooling is as effective as it is simple. 1960s Madison Heights, Michigan saw the opening of the second PTS branch in 1967. That same year, the first PTS catalog was issued. What does Dawson Shanahan’s tooling process look like? Production Tool Supply was founded in Warren, Michigan in the year 1951 1950s After achieving success, the first branch store was opened in Roseville, Michigan in 1958. Some, on the other hand, use advanced engineering software tools. time to help you make your manufacturing process the best that it can be. Many companies offering a tooling service carry out this process manually, which can be a time intensive process – therefore leading to a higher price for customers. vast expertise in time studies, along with being experts in tool design. For example: the tolerances required in the finished part, as these will affect the configuration of the tooling mechanical strength and rigidity of the tool, as this is essential to ensure workpiece accuracy, repeatability and quality cutting tool strength, which has to be sufficient to withstand machining forces, especially in high volume production and more. What factors impact on the cost of tooling?Įnsuring high-quality tooling requires a wide range of factors to be considered. In fact, thanks to modern engineering techniques the tooling costs for CNC machining and precision cold forming are relatively low in most cases. However, there is a common misconception that tooling is an expensive and sometimes cost-prohibitive process. The cost of tooling will change from project to project because it depends on so many variables. Replacing cutting tools can sap tooling budgets and is often unnecessary. So for the best parts, tooling needs to be designed and engineered to the highest quality. Production Tool & Supply is proud to announce our complete tool resharpening service.

The quality of a finished part, its properties, the speed and accuracy with which it can be produced and the repeatability of manufacture in high volume production runs, all depend on the precision and characteristics of the tooling. There are many different types of tooling, of which the most common are: work holding tools, such as jigs and fixtures cutting tools for milling and grinding machines dies for cold forming, sheet metal, forging and extrusion machines and welding and inspection fixtures. Tooling is the process of designing and engineering the tools that are necessary to manufacture parts or components. Array TAT tool readings with subsequent Temperature modelling and with the help of CAT tool revealed a production profile where 90 of horizontal section of the well produces water and only 10 of the hill produces mixture of oil and water. In this month’s blog, we address some common questions on tooling, including what it is, why it’s important and what it costs. Spectral Noise Tool (SNL) precisely located 4 zones of reservoir contributing to the production behind liner. Tooling process is an essential part of the manufacturing process, but many companies are uncertain of the best method of production and what they should be paying.

0 kommentar(er)

0 kommentar(er)